THE CLIENT

Henry Ford Hospital (HFH) in Detroit, Michigan, is the flagship hospital within the Henry Ford Health System (HFHS). HFH is a tertiary care hospital and level 1 trauma center with over 850 beds specializing in fields of cardiology, neurology, orthopedics, organ transplants, and cancer.

THE CHALLENGE

Operating HFH generates a complex and sometimes dangerous range of hazardous waste and materials. Hazardous materials include Resource Conservation and Recovery Act (RCRA) regulated hazardous, characteristically hazardous materials and related wastes including laboratory chemicals and solvents, as well as some cleaning solvents and patient care products. Universal waste, a less dangerous category of hazardous waste containing toxic materials such as heavy metals include used fluorescent lights, batteries, and leftover pharmaceuticals. Regulated Medical Waste (RMW) is potentially infectious including sharps, red bag waste, trace chemotherapy waste and pathological waste.

Operating HFH generates a complex and sometimes dangerous range of hazardous waste and materials. Hazardous materials include Resource Conservation and Recovery Act (RCRA) regulated hazardous, characteristically hazardous materials and related wastes including laboratory chemicals and solvents, as well as some cleaning solvents and patient care products. Universal waste, a less dangerous category of hazardous waste containing toxic materials such as heavy metals include used fluorescent lights, batteries, and leftover pharmaceuticals. Regulated Medical Waste (RMW) is potentially infectious including sharps, red bag waste, trace chemotherapy waste and pathological waste.

Infectious, hazardous and universal wastes are highly regulated and the most expensive components of the healthcare waste stream that require additional attention and resources to be compliant with federal, state and local regulations. HFH wanted to achieve compliance in a safe and cost-effective manner.

THE SOLUTION

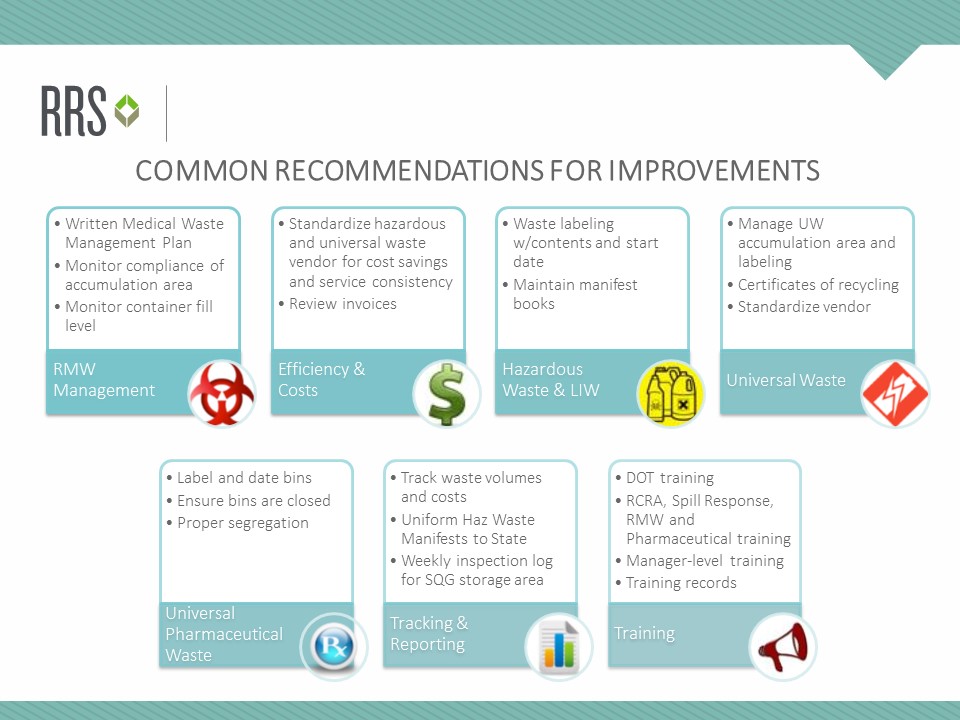

Since 2000, HFHS and RRS have partnered to make continuous improvements to the waste and recycling programs. The on-site Environmental Programs team at HFH, led by RRS, supports the infectious, hazardous and universal waste programs at HFHS locations. The program emphasis is on waste minimization and efficient and safe management of materials from the point of generation to the point of disposal. RRS took a multi-stepped approach to developing, maintaining and tracking the program.

Initially a waste assessment was conducted to identify waste generation points and storage areas, review program management manifests and training

records, as well as audit invoices. These activities enabled the identification of gaps, best practices and recommendations.

RRS continues to provide on-site expertise with waste characterizations, program and vendor oversight, training, data tracking, and reporting. Utilizing a mobile interface developed by RRS, internal waste compliance audits were established on a weekly, monthly or quarterly basis as required by federal, state and local regulations, as well as HFHS policy.

THE RESULTS

Continuous improvement efforts in auditing and documenting management of hazardous materials and waste have supported compliance and safety.

Continuous improvement efforts in auditing and documenting management of hazardous materials and waste have supported compliance and safety.

Nine priority hazardous waste accumulation areas are evaluated weekly, with others audited monthly or quarterly. 706 audits were conducted in 2014, up

from 400 in 2013. Inspections from various agencies focusing on laboratory chemical management and safety practices, underground storage tank

management, and wastewater discharge have been successfully completed.

Volumes of clinical and research lab waste have leveled off as a result of waste minimization and management of expired chemicals. Approximately 1,800 pounds of expired chemicals were properly disposed of in 2014 alone. Decanting of tissue in formalin continues to save HFH over $8,000 annually

and formalin levels have reduced due to efforts to minimize formalin use.

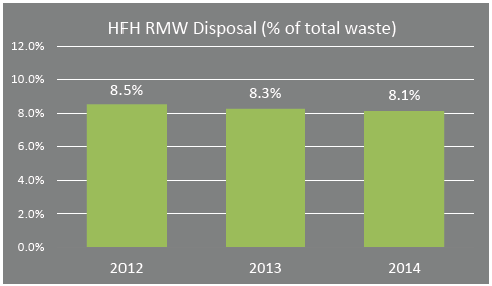

RMW volumes continue to decrease through continuous education on proper waste segregation and waste minimization. On an annual basis, over 500 employees are trained in 12 department and practice areas, and hundreds of lab personal are trained via HFHS’s online University.

HFH and HFHS join a group of forward-looking healthcare organizations moving beyond regulatory compliance to follow best practices for environmentally responsible minimization and disposal of waste.