Foam is Not a Four-Letter Word

In the 1830s, German pharmacist Eduard Simon discovered polystyrene. Today, we see foam polystyrene everywhere – cups to hold hot coffee, to-go containers to take home leftovers from the restaurant, and plates for summertime picnic outings.

Foam polystyrene has great insulating and cushioning properties due to the fact it is over 90% air. And therein lies the rub. Being 90% air means it is super lightweight, which in the product shipment world is a good thing, but in the recycling world is not a plus.

See, foam is sold and transported by weight, and it isn’t very practical to transport or market in its post-consumer, loose form. Does that mean we give up and toss our foam coffee cups in despair? Before we get overly dramatic, and possibly burn ourselves on spilled coffee, there is a solution.

A densifier is a machine that compacts loose foam polystyrene into blocks using heat or pressure. Densifiers are available in many sizes and configurations that can accommodate anything from small back room operations to large material recovery facilities (MRFs). The densified blocks can then be sold and cost-effectively transported to processors that will extrude, pelletize, and form the material into a new product.

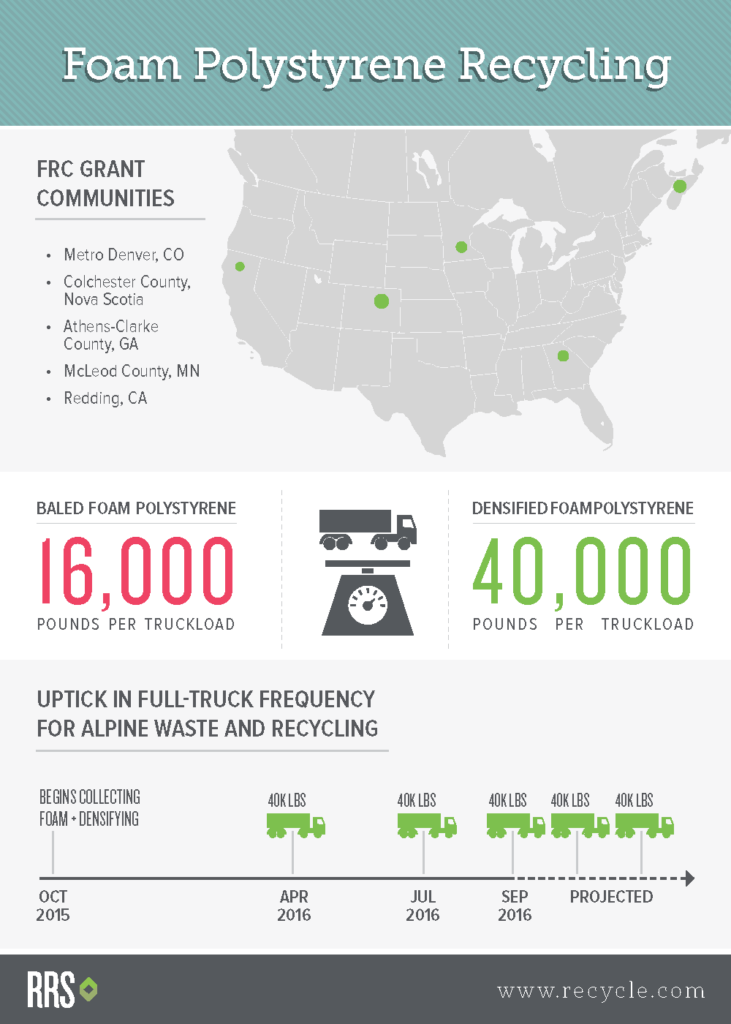

According to the Foam Recycling Coalition (FRC), “a 48-foot truckload of baled foam polystyrene weighs only around 16,000 pounds, whereas a truckload of densified foam polystyrene weighs 40,000 pounds.” In other words, 2.5 truckloads of loose versus 1 truckload of densified blocks. Okay, the math is there, but any real-world successes?

Since 2015, the FRC has awarded five grants ranging from $29,000 to $50,000 for the purpose of increasing foam recycling. Alpine Waste and Recycling operates a material recovery facility in Denver, Colo. They received a $45,000 grant from the FRC in 2015 and used it to support the purchase and installation of a foam densifier during a complete system upgrade.

“When Alpine first began densifying foam, it took approximately six months to reach a full truck load of 40,000 pounds,” stated Matt Todd, senior consultant at RRS. “As the community embraced the addition of polystyrene foam, more material was sorted and recycled to a point where they are filling a full truck almost every month.”

Does that densified polystyrene foam really get made into something new? Absolutely! To name a few products: picture frames, building products, decorative molding, file holders and packaging tape dispensers. Here is a video that takes you on the journey from polystyrene cup to picture frame: Recycle Foam

So why isn’t every community recycling foam? Densifiers are a capital investment and the layout of the MRF may need to be adjusted to accommodate system flow and equipment size. However, that initial hurdle is not impossible, and in some instances, can be overcome with technical assistance and grant programs like that offered by the FRC.

So instead of tossing our foam cups in despair, we should raise them in celebration – and maybe fill them with a little bubbly.

For more information about the FRC and the grant program, visit www.fpi.org/recyclefoam/.

Also, check out the article from Plastics Recycling Update that highlights real world successes in foam polystyrene recycling: Critical Mass.