Let’s Talk: Textile Waste

February 23, 2017

Last month in Resource Recycling magazine RRS highlighted data on textile waste in the monthly Data Corner feature. With the Data Corner starting the conversation, we wanted to continue it and get

your opinions too. Below, RRS VP Anne Johnson and Sr. Consultant Marisa Adler dive a little deeper into the current state of textile waste and textile recycling.

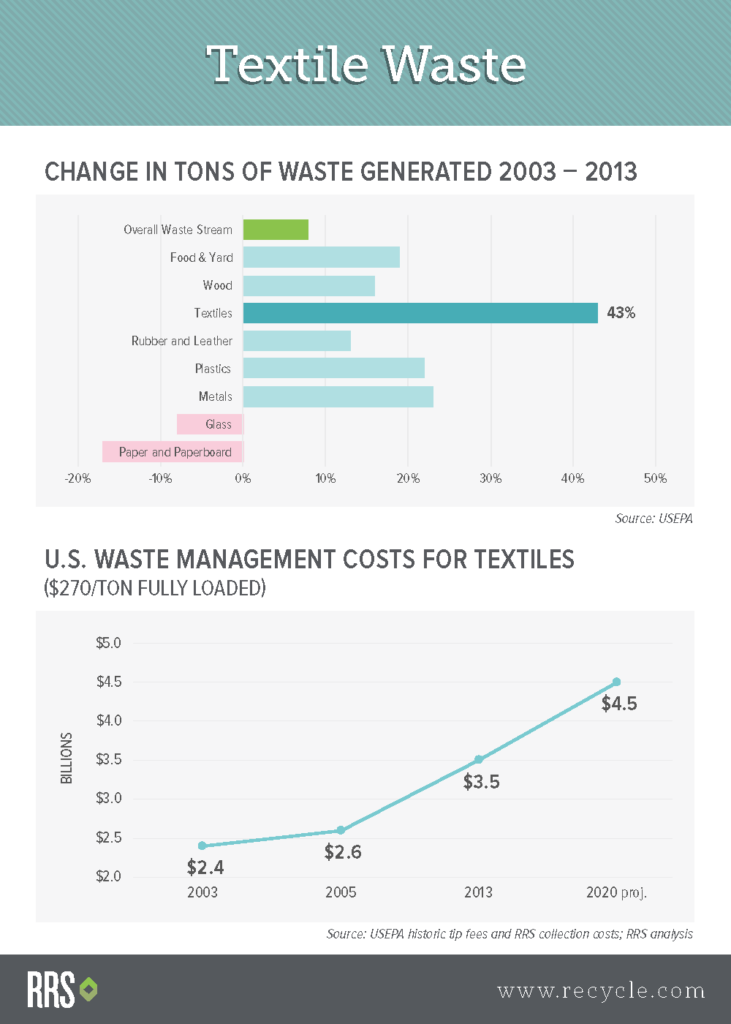

Let’s start with a look at the percentage change in overall municipal solid waste generation from 2003 through 2013 according to the US EPA. Generation of everything except glass, paper and paperboard increased. Food and yard waste, plastics and metals each increased in the waste stream by about 20%. In the ten-year span, generation of textile and apparel waste increased a staggering 43% – more than double the growth of other waste categories. And this growth has impact.

From a cost perspective, the impact is an increase in waste management costs for textiles and apparel of over $1 billion over that same ten-year period, using an average collection and disposal cost of $270/ton.

Correction: Textile management costs corrected from original January Resource Recycling magazine publication.

Why the Increase?

Let’s look at two reasons – fast fashion and a stagnant reuse and recycling rate.

Fast fashion is the result of the apparel industry producing more styles of clothing at a faster pace and at cheaper prices. This has driven consumption and in turn is driving the high disposal rate of clothing.

Compounding the overall growth in disposal of textile and apparel waste is an unwavering reuse and recycling rate. Over the past decade, the diversion rate of textiles remained stagnant at 15-16% according to the EPA, meaning that about 84% of textile waste is consistently disposed.

While there are numerous drop off programs and an increasing number of branded take back efforts, the combined impact has not been sufficient to grow overall reuse and recycling percentages at a scale to keep up with the growth in apparel and textile waste generation and disposal.

What Can Be Done?

There is no doubt that flat reuse and recycling rates leave a lot of room for improvement. There are many reasons why these rates have remained low and they will sound familiar to those in the recycling business – insufficient end markets, lack of widespread MRF textile sorting technologies, and lack of convenient consumers access to textile and apparel collection. These are topics straight from the recycling playbook. However, improving these types of solutions will help bring much needed scale.

Currently, many textile recyclers still sort materials by hand, one-by-one, into upwards of 350 different grades. The Secondary Materials and Recycled Textiles (SMART) association reports that once the textiles are sorted, 45% are sold and reused as secondhand clothing, 30% are used for rags, 20% are turned back into fiber, and 5% are unusable and discarded. Some companies have better technologies than others, however sophisticated conveyor and optical sorting systems are not common, although they do appear to be emerging as the technology of the future.

Next Steps

What are the critical issues that need to be addressed to more effectively tackle this textile mountain? What are the systems that work well now and where are there gaps? To know what is needed, we need input from all players – municipalities, brands, retailers, designers, non-profit collectors, recyclers and sorting companies, as well as consumers – to find truly viable solutions. Let’s hear from you – where do we start?