The Client

Michigan State University (MSU) is the nation’s pioneer land-grant university. Founded in 1855, MSU is now home to 49,000 students and a faculty and staff of 11,000. A unit of Infrastructure Planning and Facilities, MSU’s Sustainability Office leads research, data collection, programming, outreach, and communications for the Be Spartan Green environmental stewardship initiative.

The Challenge

MSU recycling started with an office paper recycling program in 1988. Since then, the operational and administrative scope of campus recycling has grown along with other campus sustainability initiatives.

In 2006 MSU embarked on a project to build a facility and programs that could combine waste, recycling and surplus materials management in a manner that meets environmental stewardship objectives including:

- Maximum recovery,

- Minimal waste to landfill,

- LEED principals in design and construction, “Green” building and equipment,

- Public outreach including educational space for public and student use.

MSU wanted to develop a system to optimize material flow, by identifying collection strategies that deliver material to the proposed processing facility in a form that minimizes handling in collection and processing. Significantly, multiple programs engaged in material recovery and reuse were considered for inclusion in a new high capability facility. A formal review of loading area limitations and dock equipment requirements for each site was essential to assure that collection containers at loading areas allowed efficient transition into material mixes that matched new processing capabilities.

The Solution

RRS began this project by conducting an initial needs assessment that involved meeting with operations and service personnel and examining the current state of the program. Utilizing that information, a best practice benchmarking was conducted comparing MSU’s program to other leading university programs.

Next, RRS conducted a housing division recycling services feasibility assessment that provided recommendations for operations and outreach to efficiently collect material from student housing.

A regional intergovernmental project feasibility assessment was conducted that involved interfacing with the surrounding municipalities and provided insight to the recycling needs of the greater community.

RRS provided preliminary facility engineering, as well as led the request for proposal (RFP) process and procurement negotiations for the MRF equipment.

Finally, options and alternatives were presented to MSU with an extensive Recycling Center Study with business case justification.

The Result

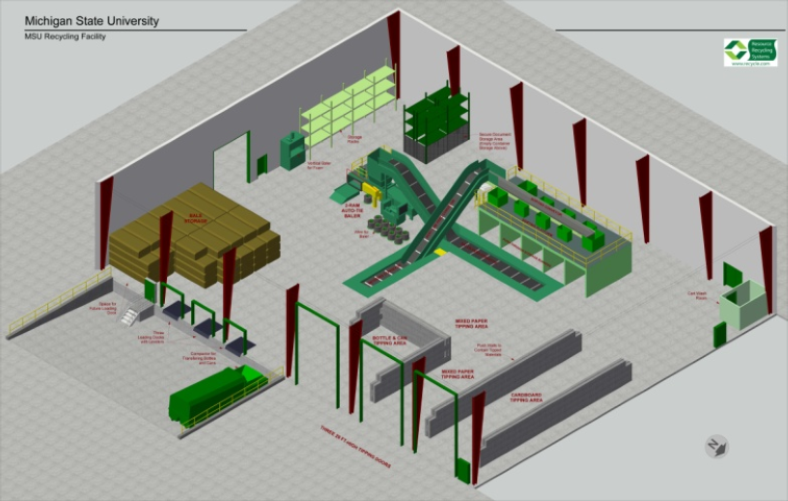

MSU decided to proceed with a new on-site flexible facility incorporating a MRF, Surplus Goods Management Facility and Surplus Retail Store, investing $13.3 million dollars into the project with the expectation of a 10-year payback. The new facility processes corrugated cardboard, commingled paper, commingled bottles and cans; handles special materials; and includes a campus drop-off. RRS provided operations, efficiency, design and transition management for the project implementation.

The new 74,000 square foot facility completed construction in 2009, collected 3.6 million pounds of recyclables in its first year of operation, and achieved the coveted US Green Building Council LEED Gold Certification. Advanced sorting and baling of recyclables allows for the materials to be sold at higher prices to processors, generating more revenue for MSU. The MSU Surplus Retail Store, selling University surplus property, achieved sales levels approaching $3 million. The program continues to grow with the formation of MSU Sustainability (a merger of MSU Recycling, Surplus Store, Storage, Waste Management, MSU Bikes, and the Office of Campus Sustainability) and the formation of the Be Spartan Green Team, encouraging student participation.